Controlling hazardous areas using restricted area software

Restricted area software allows monitoring access to restricted or hazardous areas on a mine site is an important part of keeping employees safe. Potential hazards can range from the operation of heavy machinery or equipment to environmental dangers and operating within confined spaces. Using restricted area software can assist with tracking personnel across hazardous areas, improving safety across the controlled areas.

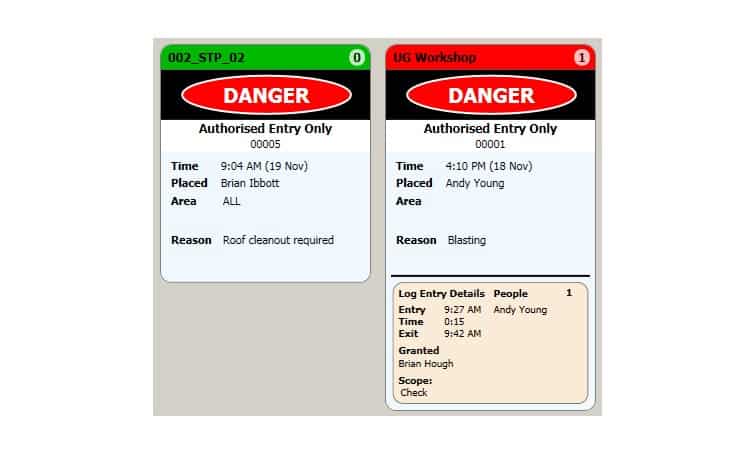

MICROMINE’s fleet management and mine control solution, Pitram, provides the tools for tracking personnel across hazardous or restricted areas. This is achieved through the controlled areas module which alerts supervisors whenever the duration or number of personnel within an area has been exceeded. Pitram is a restricted area system used by mining operations worldwide.

Meeting safety standards

When establishing a restricted area, mine supervisors can set parameters based on the required safety standards required. For example, in a tight or confined underground space, restrictions may be put on the number of personnel allowed within the area in order to reduce congestion. Requirements may also be put on the type of equipment personnel are required to wear while in the area. This could include a high visibility vest in poorly lit areas or a hardhat for areas where objects are at risk of falling. Other possible safety requirements that can be monitored by restricted area software include the duration personnel are present within a restricted area, working from heights monitoring or if staff are working off-site and regular contact times are required.

Pitram will then allow the control room to monitor activity within each area on-screen, providing increased control over operations. Any activities in or movement through an area is logged, allowing control room operators to act when an incident occurs or if safety standards have been breached. The control room is then able to use the logged data for reporting purposes if required.

Restricted area software: Choosing Pitram for your mine safety

Utilising restricted area software like Pitram improves the control mining operations have over dangerous or restricted areas on-site. Improved control enables the likelihood of potential incidents to be reduced which assists with improving the overall safety of employees throughout the operation.

Further reading

>Learn more about Pitram’s restricted area software.